Product List

- Welding Manipulator

- Welding Positioner

- Welding Rotator

- Adjustable Welding Rotator

- Conventional Welding Rotator

- Special Welding Rotator

- Welding Turntable

- CNC Cutting Machine

- Laser Cutting Machine

- CNC Flame Cutter

- CNC Plasma Cutter

- CNC Table Cutting Machine

- H Beam Production Line

- Wind Tower Production Line

- Robotic Welding Automation

Welding Turntable (Welding Floor Turntable)

Description of Welding Turntable:

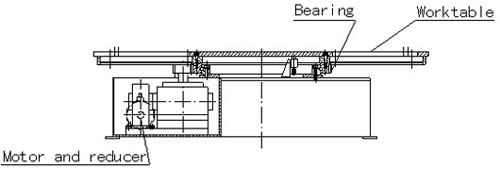

This welding turntable mainly consists of a worktable, a bearing, a base, a motor, and a speed reducer. And its worktable can be made according to specific requirements of our clients. Besides, some special welding turntable can be used in pressure vessel welding, round structure welding, and many other circular welding.

ABK Machinery is a professional welding floor turntables manufacturer in China. Our welding turntable is mainly composed of a worktable (could be customized), bearing, base, motor and reducer. It is used for welding and assembling the work pieces. By attaching the work piece on the turn table, our turn table rotates the work piece for automatic welding. It is an efficient way to improve the welding quality and reduce work load. Our welding turntable could be applied to industries like pressure vessel making, petrol industries, chemistry, power stations, transportation, ship making, steel and more. You will be satisfied with our welding turntable, which is exported to Brazil, Germany, France, Italy, Vietnam, Singapore, Spain and other countries. Special welding turntable is used in press vessel end, round structure welding and any other circle welding.

Features of Welding Turntable:

1. On the work table, there are 6 T slots where T bolts could be installed for the tight fastening of the work piece.

2. The rear side is welded with 6 stiffeners to increase the rigidity and reduce the deformation of the work table.

3.We adopt worm gear box.

4. Stepless speed regulating facilitates reliable performance and provides a wide speed regulating range. It is easy to control and maintain and is suitable for different welding requirements.

5. The base is robust thus allowing stable turning.

Sketch Map of Welding Turntable:

| Load | Turning Velocity (rpm) | Worktable diameter of (mm) | Motor power (kw) | Speed regulation way |

| 300kg | 0.1-1 | Φ600(or customized) | 0.37 | Variable frequency speed control |

| 1t | 0.05-0.5 | Φ1200(or customized) | 0.75 | |

| 3t | 0.05-0.5 | Φ1400(or customized) | 1.5 | |

| 10t | 0.05-0.5 | Φ2000(or customized) | 2.2 | |

| 20t | 0.05-0.5 | Φ2500(or customized) | 4 | |

| 30t | 0.04-0.4 | Φ3000(or customized) | 4 |

Related Products

- CNC Cutting MachineCNC cutting machine achieves cutting process by thermal cutting mode. The gas such as oxygen, ethyne and propane can be employed as combustible gas. The CNC cutter can also introduce plasma device or laser head to accomplish the cutting process. The CNC cutter allows cutting job fulfilled through the computer controlling the equipment, which overcomes the shortages...