Product List

- Welding Manipulator

- Welding Positioner

- Welding Rotator

- Adjustable Welding Rotator

- Conventional Welding Rotator

- Special Welding Rotator

- Welding Turntable

- CNC Cutting Machine

- Laser Cutting Machine

- CNC Flame Cutter

- CNC Plasma Cutter

- CNC Table Cutting Machine

- H Beam Production Line

- Wind Tower Production Line

- Robotic Welding Automation

Welding Positioner (Tilt-Turn Positioner)

Description of Welding Positioner:

We are professional manufacturer of welding positioner in China. The welding positioner also called tilt-turn positioner, weld turntable or gear driven positioner. It mainly consists of a working table, turning device, overturning device, electricity-conducting device, stander and electric cabinet. The working table is driven by the turning device which has 6 T style slots to ensure the work piece is strictly fastened on the working table.

Features of Welding Positioner:

Achieving the down-hand weld position is essential for the fabrication and assembly of noncylindrical workpieces.

Range of welding positioners provides the quickest means of both rotating and tilting through 360 degrees while allowing maximum access to the workpiece.

Free-standing, robust all steel fabrication, variable speed table rotation, round or square "T-slotted" tables with extension arms on some models, table tilt, table elevation, steel gears, the latest enclosed electronic controls, efficient built-in earth, remote push button pendant control with a huge range of optional extras make Positioners your number one choice.

1. The weld table turning device is made up of a motor, a speed reducer and a swing set.

2. Frequency conversion and speed regulation is used for speed change.

3. Stepless speed regulation, easy control and cheap maintenance.

4. The overturn device is mainly made up of an electric motor, cycloidal gear speed reducer, worm wheel speed reducer, semicircular gear.

5. Either end of the output shaft of the overturn device is installed with a semicircular gear.

6. One end of the electric conduction device is connected to the swing set while the other end has an electric conducting shaft. It is directly propped to the working table, allowing the welding current to be directly transmitted from the working table.

7. The stander is of a box structure, allowing high loading capacity. It is made of Q235-A steel with annealing and finish machining to eliminate the welding stress deformation.

We offer all kinds of welding positioner, as follows:

1. Welding Bench Positioner

2. Welding Tilt Positioner

3. Welding Turn Positioner

4. Custom Special Welding Positioner

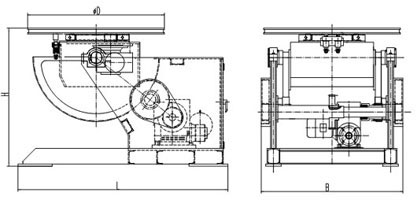

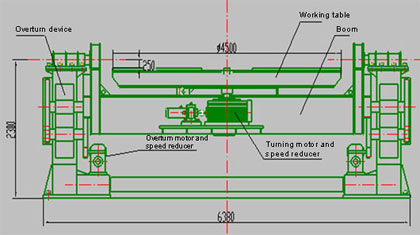

Sketch Map of Welding Positioner:

Pursue:

1: The HBJ type gear driven positioner sketch map

Remarks:

1. The dimension provides a reference only.

2. This product can be designed according to consumer needs.

| Model | HBJ-01 | HBJ-03 | HBJ-06 | HJB-12 | HBJ-30 | HBJ-50 | HBJ-100 | |

| Rated load capacity (kg) | 100 | 300 | 600 | 1200 | 3000 | 5000 | 10000 | |

| Turning speed (rpm) | 0.4-4 | 0.1-1 | 0.09-0.9 | 0.05-0.5 | 0.05-0.5 | 0.05-0.5 | 0.05-0.2 | |

| Overturn speed (rpm) | handle | 1.1 | 0.67 | 0.23 | 0.14 | 0.14 | ||

| Diameter of working table (mm) | ¢400 | ¢600 | ¢1000 | ¢1200 | ¢1400 | ¢1500 | ¢2000 | |

| Turning angle (°) | 0-120 | 0-90 | 0-90 | 0-120 | ||||

| Motor power (KW) | Turning | 0.06 | 0.37 | 0.75 | 1.1 | 1.5 | 3 | 5.5 |

| Overturning | 0.75 | 2.2 | 1.5 | 3 | 5.5 | |||

| Speed regulation type | Stepless frequency conversion | |||||||

| Max gravity distance (mm) | 100 | 100 | 100 | 150 | 200 | 300 | 400 | |

| Max eccentricity (mm) | 150 | 150 | 150 | 200 | 200 | 300 | 400 | |

| Max rotating diameter when 90° overturned (mm) | ¢600 | ¢800 | ¢1500 | ¢2050 | ¢2100 | ¢2500 | ¢3240 | |

Above 10ton, we will produce with customer’s requirment.

Related Products

- Welding RotatorThis welding rotator, also known as welding turning roll, tank rotator or pipe rotator. It is mainly used for welding of pipes, API pipes, heat exchangers, mounted vessels, boilers, LPG bullets, barrels, pressure vessels and tanks. This welding rotator mainly consists of a base, driving rollers, idlers, electric cabinet, brackets, transmission device, and power-driven...