Product List

- Welding Manipulator

- Welding Positioner

- Welding Rotator

- Adjustable Welding Rotator

- Conventional Welding Rotator

- Special Welding Rotator

- Welding Turntable

- CNC Cutting Machine

- Laser Cutting Machine

- CNC Flame Cutter

- CNC Plasma Cutter

- CNC Table Cutting Machine

- H Beam Production Line

- Wind Tower Production Line

- Robotic Welding Automation

Adjustable Welding Rotator

Description of Adjustable Welding Rotator:

Our company design and manufacture adjustable welding rotator based on absorbing the advantages of similar products at home and abroad. The HGK-type adjustable welding rotator is mainly composed of a drive rotator, an idle rotator, an electric control box, and a remote control box. It is designed for handling and automatic welding circular metal containers, and it mainly used in oil industry, press vessel field, boiler, chemical tank, and many other round workpiece fields. It can used in all kind of the diameter, and frequency conversion setting, low sound, work placidity.

The HGK type adjustable welding turning roll have advantages of the same kinds of products in domestic and international. We design and make them according to the requirments of the pressure ve-ssel factory. This adjustable welding rotator is designed and manufactured to better meet increasing demands for pressure vessel manufacturers, so it enjoys more advantages over other similar products at home and abroad. It can be used to deal with a wide range of diameters. It features easy operation, high quality, low noise, advanced technology, etc. Besides, this adjustable pipe rotator has obtained CE certificate, and is quite popular among clients in Brazil, India, Jordan, South Africa, UK, Poland, Spain, etc.

We Offer Adjustable Welding Rotators, As Follow:

1. Adjustable Pipe Rotator & Tank Rotator

2. Adjustable Vessel Rotator & Vessel Turning Roll

3. Adjustable Wind Tower Rotator

Characteristics:

1. Self-regulating core welding turning roller consist of a single active rack and a slave rack ,active rack and slave rack are all have four rollers.

2. Roller use for steel glue ,steel core roller outsourcing of heat-resistant rubber, bearing the weight of large, rubber floors long life, non-deformation, non-unglued.

3. The distance of rollers can be adjusted automatically according to the diameter of work piece.

4. VFD speed control, it is stable and precise.

5. Reducer selection of high-quality cycloid reducer, planetary reducer with the structure and rolling contact transmission mode, with durable advantages of small size, while a small loss of efficiency, mechanical efficiency of up to 90%.

6. Electric control system consist of electrical control box and hand control boxes.

7. Electric control box consist of empty open, inverter, microprocessor board, Manipulator remote control operation, simple and reliable, with a jog and speed function.

8. With a linkage interface, with manipulator and submerged arc welding machine consist of automatic welding center operations to achieve linkage.

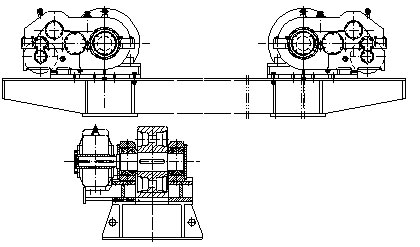

Sketch Map of Adjustable Welding Rotator:

| Type | HGK-2 | HGK-5 | HGK-10 | HGK-20 | HGK-40 | HGK-60 | HGK-100 | HGK-200 | HGK-300 | HGK-500 | |

| Load | 2 | 5 | 10 | 20 | 40 | 60 | 100 | 200 | 300 | 500 | |

| Wheel diameter(mm) | 250 | 250 | 300 | 350 | 450 | 500 | 550 | 700 | 800 | 900 | |

| Wheel (mm) | 100 | 160 | 196 | 210 | 220 | 200(metal) | 220(metal) | 300(metal) | 300(metal) | 300(metal) | |

| Vessel Diameter | Min(mm) | 150 | 250 | 300 | 500 | 500 | 500 | 800 | 800 | 1000 | 1000 |

| Max(mm) | 2000 | 2800 | 3200 | 4500 | 4800 | 5000 | 5000 | 5000 | 6000 | 8000 | |

| Wheel velocity(m/h) | 6-60 | 6-60 | 6-60 | 6-60 | 6-60 | 6-60 | 6-60 | 6-60 | 6-60 | 6-60 | |

| Power of motor(kw) | 2*0.18 | 2*0.37 | 2*0.55 | 2*1.1 | 2*1.5 | 2*2.2 | 2*3 | 2*4 | 2*5.5 | 2*7.5 | |

ABK Machinery range of welding rotators and tank turning rolls offer the most comprehensive range of any manufacturer all available for sale or rental. Our range includes pipe rotators from 1 tonne up to 10 tonnes, heavier duty welding rotators up to 1000 tonnes capable of rotating vessels up to 10 metres in diameter.

Whether you require the need to position and weld a small pipe section, flange or elbow, a large pressure vessel or a complex wind tower or double jointing line, ABK Machinery has the solution to rotate and position your workpiece to maximise your production efficiency and guarantee to solve your welding and handling requirements.

Related Products

- Conventional Welding RotatorThe HGZ type conventional welding rotators have advantages of the same kinds of products in domestic and international. We design and make them according to the requirements of the pressure ve-ssel factory. Our conventional welding rotator is mainly used for handling and automatic welding circular metal containers, and can be widely applied to pipes, heat exchangers, vessels, boilers, LPG bullets...